INTRODUCTION An industrial shed is any building structure used by the industry to store raw materials or for manufacturing products of the industry is known as an industrial building. INTRODUCTION TO STEEL DESIGN AND CONSTRUCTION 8 II.

Pdf On The Optimization Procedure Of Rolling Mill Design

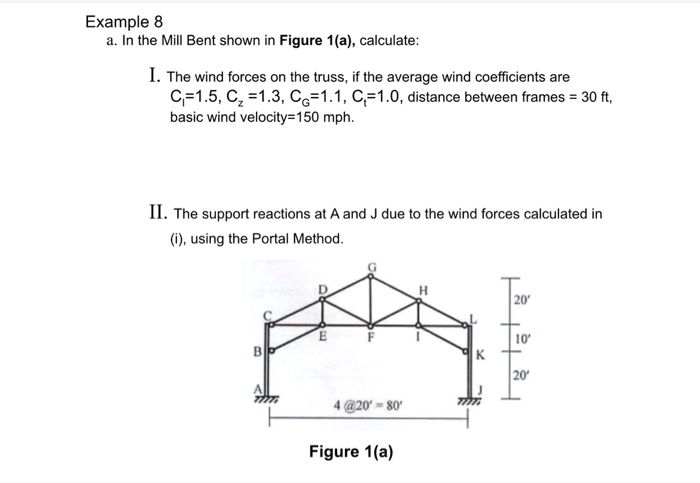

The design of an industrial mill building involves myriad assumptions and parameters.

. Furthermore allow a more generous bend tolerance - 007 as tighter tolerances while achievable will result in higher costs. Determine plate cantilever dimension m or n in direc- tion of applied moment. The overall design of the conveyor is shown below in Figure 4.

Principles of design and detailing into a common practical procedure which may be used as a guide. However it is necessary to manually check the design especially for ductile detailing and for adopting capacity design procedures as per IS 13920. Designofamodernsteel millbuilding by ralphandersonbennitt bsuniversityofillinois1913 thesis submittedinpartialfulfillment oftherequirementsforthe degreeof civilengineer in thegraduateschool ofthe universityofillinois 1917.

The core idea of this paper is to present an efficient 3D shape synthesis. LRFD DESIGN OF CALIFORNIA BRIDGES SHEET 1-1 OF JOB TITLE BENT DESIGN ORIGINATOR Bob Matthews DATE 10192007 JOB No. Are required piles prebent in the mill may be used.

Step 1 Obtain loads from superstructure. B41 Design Procedure for a Small Moment Base 1. MODELING AND ANALYSIS OF THE BUILDING 31.

PROCEDURES AND METHODS Design Procedure After the initial design ideas were drawn on paper AUTOCAD 2014 was used to draw the conveyor system in an electronic format because of its versatility dimensional preciseness and editing capabilities. THE STEEL PROCESS FROM DESIGN THROUGH ERECTION 10 A. Connecting angles q in the range from 30 to 45 are recommended.

Detail Drawings 28 4. Mill Design Example. Design miming is a process through which a person gesticulates move hands to describe a real-world physical object.

Erection Drawings 26 3. Hot rolled steel which obtains its high strength from a mill heat treatment and tempering process. On the other hand a right hand screw will be turned clockwise and its helix will appear to.

Strength I Load Combination will be used to design the reinforcement. Example 1 - Calculating the elastic section modulus Sx and plastic section. Parameters is a critical stage in design process.

Bent piles In general junction piles are made by welding in accordance with EN 12063. N d 2 3 in B bf 2 3 in 2. The live load reactions LL dead load of structural components DC and dead load of future wearing surface DW will be needed to design the end bents.

Design of Screws Fasteners and Power Screws pd S Dtan or tan p d D S. The design was carried as per IS 4562000 for the above load combinations. The Pinson plant has been described in some detail by Mcquiston and Shoemaker in.

Design and construction industry in a design office on a construction site. Some in-fill construction may necessary appropriate and permitted. This paper is concerned with the stability design of steel columns subjected to concentrated gravity loads within their unsupported lengths.

In steel storage rack design standards ECS 2009 ERF 2012 RMI 2012. M N 095d 2 n B - 080bf 2 3. October 11 2011.

REVIEWER DATE SECTION 10 BENT CONFIGURATION Note. The bridge configuration was taken from Massachusetts Avenue Overcrossing of Interstate 215. Choose trial base plate sizes B and N based on geom- etry of column and four-anchor requirements.

The Mill property will be approached as a three-building complex. To depend on existing design codes such as CISC NBC AISC AISE BS449 etc and to follow the normal design procedures is necessary but not in itself sufficient to produce a proper practical structure. In the current state of the art there is disagreement about the validity of many of these assumptions and parameters.

TxDOT Bridge Division. Such a threaded screw will have to be turned counter clockwise to engage the mating nut. If deviation angles exceeding the values given in Table 21.

Such columns include mill building columns and drive-in rack uprights. The Mill re-use project will be mixed-use. A procedure to optimize the rolling mill design will be discussed in this article.

A feasibility study was undertaken in 1979 by a consortium of three Toronto-based mining companies arid a Reno-based exploration company. Advanced Bill of Material 24 2. Reinforcement cut bent and bundled for delivery to site The Reinforcement Handbook provides information about the use of steel.

51 If the helix on the outside surface ascends from right to left the thread is left hand. Various rolling models and optimization methods are applied in each step. Example 9 - Calculating the design and allowable compressive strength per LRFD and ASD for a pinned column braced in the strong and weak directions.

Structural Steel Design Fabrication and Construction Jamie F. Connection Design 18 4. Main Member Design 13 2.

Adopting simple design procedure and IS specifications. Similarly other types of pile caps can also be designed following the same procedure. Paint area over Bent Weathering Steel.

Private-sector involvement in the Mill re-use project may necessary. Computer packages could be used for ease of design while verifying the design outcome with simple calculations. After the bar is.

Mill Building Design Procedure Engineering Journal American Institute of Steel Construction Vol. It is nevertheless possible to have angles up to 90. Keywords Warehouse Load Combination Dead Load Live Load Wind Load Nodes.

Procedures A490 bolts require impact wrenches that might not be available Max Spacing. Milling artifacts in the main Mill building must remain in that building. However when the number of piles is increasing in a pile cap the manual calculation becomes more complicated.

Engineering Calculations 22 B. Pinson Mining Company was formed to develop a gold orebody located in northern Nevada near Winnemucca. Painted Steel System IV non coastal new construction.

The forming process and the fact that dimensional variation is introduced at each bend dimensioning in a single direction parallels the process and helps to control tolerance accumulation. Secondary Member Design 17 3.

Roll Bending An Overview Sciencedirect Topics

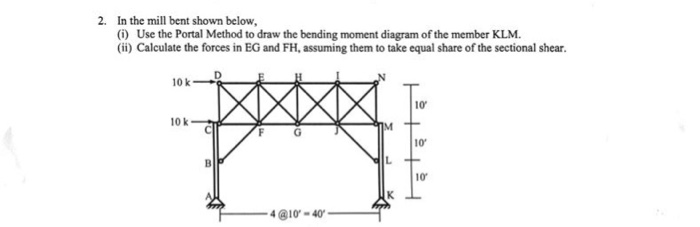

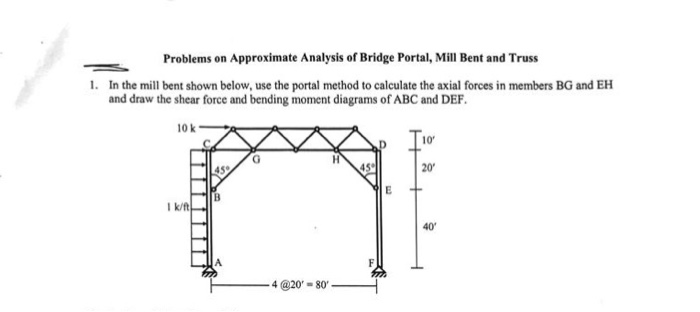

In The Mill Bent Shown Below I Use Chegg Com

Structural Analysis Design Ii Mill Bent Video 4 Youtube

Solved In The Mill Bent Shown Below Use The Portal Method Chegg Com

What Is Mill Bent In Industrial Buildings

Solved For The Portal Frame A K A Mill Bent Shown Below Chegg Com

Example8 A In The Mill Bent Shown In Figure 1 A Chegg Com

Pdf On The Optimization Procedure Of Rolling Mill Design A Combined Application Of Rolling Models

0 comments

Post a Comment